Taxpayer subsidies for transition to natural gas (NG) as transportation fuel for over-the-road trucking is fraught with dangers to the nation's economic and environmental future. These page subheadings link to specific NG threats and urge investment to convert to a sustainable domestic energy-powered transportation system--and ultimately a fossil fuel-free solution--electrified rail:

- Subsidizing T. Boone Pickens is Too Costly & Plain Wrong !

- Steel Interstate rail is the better approach

- Hidden External Costs

- Massive road construction need not be inevitable

- Hidden Internal Costs

- Energy conversion losses are unacceptable

- A Transition Costly to the Public

- But beneficial for an energy billionaire

- Market Penetration Barriers

- That old chicken or the egg thing

- Environmentally Safe? NOT!

- A drilling practice threatens water & human health

- Sustainable Transportation Fuel?

- Coal better for the climate than hydro-fractured "fracked" NG!

- Safety? We Can Do Much Better!

- Moving freight on trains is safest

- Productivity & Labor Concerns

- The right choice enhances competitiveness

Image: Craig Thorpe

Image: Craig Thorpe

The Steel Interstate System (SIS) can speedily move America's inter-city freight will avoid the costs, environmental, safety, and health problems related to a unprecedented and economically unsound conversion of heavy trucking from diesel to natural gas. An electrified SIS will meet the goal of a freight system operating on domestically produced energy. That energy can be completely renewable and sustainable, virtually eliminating greenhouse gas emissions from U.S. mid- and long-distance freight movement. Unlike NG trucking conversion, the SIS will provide a greatly expanded fossil-fuel free inter-city passenger service as a national dividend.

Take action NOW! Contact your senators and representative to oppose subsidies to convert big trucks to run on natural gas.

Too Costly: Natural Gas Trucks Us Down the Wrong Road! Steel Interstate Electrified Rail is the Right Track for the Future.

Converting inter-city trucking from diesel to natural gas (NG) fuel would be astonishingly expensive for the return on investment. This proposal would drive up NG prices for all customers. Yet, legislation offered to Congress would begin to do just that. NG trucking would require costly engine conversions, an entirely new refueling infrastructure, and hundreds of billions of dollars in hidden road construction costs and wasted energy. NG costs for residential, commercial and industrial customers will climb, too; driven up by consumption of NG as a transportation fuel.

Recent legislation including HR 6564: Oil Independence for a Stronger America Act of 2010 and S. 3815: Promoting Natural Gas and Electric Vehicles Act of 2010, would subsidize a transition for over-the-road trucking from diesel to natural gas (NG) fuel. These proposals purport to promote domestically-sourced and cleaner-burning fuel, unjustifiably claiming to reduce greenhouse gas emissions. NG is the wrong fix for freight transportation policy. It is no fix at all. The proposal mis-allocates limited resources and time which must be committed to converting mid- and long-distance freight trucking away from CO2-emitting fossil fuels altogether. Public resources should be used to develop a faster, safer, cheaper, greener, more economically productive transportation alternative, serving not just freight but passenger traffic as well -- the North American Steel Interstate System.

Senate Majority Leader Harry Reid (D-NV) sponsored S. 3815 in the 111th Congress. Oil billionaire T. Boone Pickens helped to promote this federal legislation. Pickens wants to increase the inventory value of his vast reserves of NG. To increase the cost of NG, he came up with the idea of increasing the market for gas by turning it into a transportation fuel.

Pickens had incorporated into the bill a $65,000 tax credit subsidy per heavy truck conversion to NG. According to Mr. Picken’s estimate of 8 million U.S. over-the-road heavy trucks, subsidies could ultimately stretch out to cost $520 billion.[Klein, P., The Natural Gas Man, The American Spectator, July 22, 2010] Employing a reasonable average cost for the Steel Interstate construction of $15 million per mile and applying that same $520 billion to build it, the result is 34,667 miles of Steel Interstate, or virtually enough money to construct the entire U.S. Steel Interstate System (SIS).

The House bill was introduced in December, 2010, during the waning hours of the 111th Congress. HR 6564, sponsored by Jay Inslee (D-WA), gives a nod to diversion of truck freight to rail (a minimalist goal of 10% shift in market share) and even to studying electrified rail. HR 6564 contained a great deal of laudable legislation to move the nation away from oil dependence by increasing energy and fuel efficiency in homes and vehicles and encouraging market penetration of electric cars. However, the bill also designates an apparently unlimited tax credit for NG truck conversion, upping the ante to $80,000 per truck. Neither S. 3815 or HR 6564 passed. It is expected that similar NG conversion subsidy legislation will be introduced in the 112th Congress.

A new NG-powered truck engine will last a few years; then the expenditure will be lost. But, if deployed to build out the infrastructure of a national Steel Interstate, that capital remains on the ground for a century to come.

The North American Steel Interstate Coalition agrees that Mr. Pickens has identified the area of the transportation system most in need of transformation—over-land freight movement. However, public policy direction should not be dictated by those who promote a particular approach from which they also stand to personally profit. This is the case with Pickens' involvement with these bills. When public policy is developed in this manner, true transformation is ignored.

The Steel Interstate System (SIS) of efficient, fast, high-capacity, electrified railroads offers a superior opportunity to power freight shipments using more appropriate, domestically-generated electricity. This SIS would dramatically reduce national fuel consumption, opening the door to eliminating fossil fuel use for most inter-city freight shipments altogether.

Image: Craig Thorpe

While also achieving Pickens' goal for converting to domestic energy, the Steel Interstate would offer far greater reductions in greenhouse gases. There is evidence that switching from diesel to NG-powered vehicles will actually increase national greenhouse gas emissions. The SIS also offers greatly improved traffic safety, and supports better land use and development policies than Pickens bill. The Steel Interstate System would also create an interconnected, nationwide passenger system faster and far more extensive than what AMTRAK currently provides. Public safety greatly benefits from diverting truck and auto traffic to the railroad, separating it from highways altogether.

Committing to a program of converting the nation’s freight system to natural gas-powered trucking would ultimately cost the public hundreds of billions of dollars. This expenditure would waste the financial resources needed to partner with railroads to upgrade rail infrastructure. This is a partnership America desperately needs--bringing the wealth of private railroad capital to bear upon the public need for efficient, safe, speedy, and cost-effective movement of people and freight.

Take a look under the surface at the long-term cost consequences of the Pickens bills for NG truck conversion proposals. You will see that these consequences are clearly taking us down the wrong road. The SIS puts us back on the right track!

Massive Road Construction ~ The Hidden External Cost of Natural Gas Trucking

The Pickens proposal maintains and increases future dependence on trucks for hauling mid- and long-distance freight. This dependence would also require an immense, costly, and destructive highway building scheme to accommodate truck freight growth. To reduce demand for more and more highway capacity, we must devise a plan to reduce vehicle miles traveled (VMT). Instead the Pickens bills would increase VMT and drive new proposals for hundreds of billions of dollars in new highway construction.

The Pickens proposal maintains and increases future dependence on trucks for hauling mid- and long-distance freight. This dependence would also require an immense, costly, and destructive highway building scheme to accommodate truck freight growth. To reduce demand for more and more highway capacity, we must devise a plan to reduce vehicle miles traveled (VMT). Instead the Pickens bills would increase VMT and drive new proposals for hundreds of billions of dollars in new highway construction.

For over 60 years powerful interests in the U.S. have implemented policy to construct a vast highway infrastructure. As the number of vehicles increases over time, new proposals for more highways and expanded number of lanes on existing highways always surface.

As a direct consequence in many states, the existing highway system is deteriorating sometimes to dangerous conditions. Three years after I-35W bridge collapse disaster in Minnesota, “150,000 bridges -- nearly one in four -- still are considered deficient, according to the latest data from the Federal Highway Administration.” [Herb, J., 150,000 U.S. bridges are still rated 'deficient,' Minneapolis-St. Paul Star Tribune, July 21, 2010] Trucks operating within legal weight limits are constantly tearing up these highways.

Deterioration of our roads and bridges is no accident. Rather, it is the direct result of countless policy decisions that put other considerations ahead of the pressing need to preserve our investment in the highway system. Political forces often undermine a strong commitment to maintenance. Members of Congress, state legislators and local politicians thrive on ribbon-cuttings. Powerful special interests push for new and bigger highways. Meanwhile, federal and state policies—which should provide strong guidance in the wise use of taxpayer dollars—often fail to achieve the proper balance between building new infrastructure and taking care of what we already have built.[Madsen, T. Davis, B., Braxendall, P., Road Work Ahead: Holding Government Accountable for Fixing America’s Crumbling Roads and Bridges, U.S. Public Interest Research Group Education Fund, April, 2010]

Over time, projected freight movement growth would require tens of thousands of lane-miles of new highway to accommodate a growing NG-fueled truck fleet. Building additional highway lanes destroys land and adjacent private businesses. It degrades historic and visual resources. Highway construction is very expensive and disruptive, especially in urban and suburban areas. More highway lanes promote additional sprawl with attendant land use, traffic congestion, safety, fuel consumption and pollution costs.

Shipping companies are demanding heavier, longer, and faster trucks to reduce their costs, causing road maintenance costs to spike up further. Our nation’s highway infrastructure is already crumbling and congested under the weight of today’s heavy truck traffic, but improved rail service can meet these needs and help the nation avoid highway construction and maintenance costs.

The I-81 Corridor in Virginia illustrates the pressure for new highway capacity for trucking. From 2003-2008, RAIL Solution [A founding regional initiative of the North American Steel Interstate Coalition.] successfully fought a plan by KBR to more than double the size of rural I-81 in Virginia. I-81 is a major freight haulage corridor from the Northeast and Canada through the Appalachians with direct connections to the Mid-South and Texas—including ports of entry in New York, Boston, Philadelphia, Norfolk, New Orleans, and Laredo, TX. (Formerly Kellogg Brown & Root, KBR was then a global engineering and service division of the Halliburton Corporation.)

The KBR-assembled consortium of road building and financial interests called for four exclusive truck lanes in the middle of four “mixed use” lanes. Their proposal was tantamount to a corporate takeover of I-81. Heavy tolls were planned to pay for the doubling of lanes, additional right of way, and massive interchanges, allowing trucks to enter and exit truck-only lanes. The plan was weighted down by the bloated $13 billion price tag, to be borne by users including passenger car drivers. The highway would have created a giant asphalt scar across 325 miles of Virginia’s most beautiful rural landscape—the Shenandoah Valley, the Valley of Virginia, the Roanoke Valley, New River and Holston River valleys. The giant truck toll road would impact the serenity of 10 Civil War battlefields and other historic resources.

2005 RAIL Solution rally for rail in I-81 Corridor, Abingdon, VA. Photo: Kathy Shearer

It appeared that the Commonwealth of Virginia was willing to sacrifice this rural landscape in the interest of accommodating through-state trucking. But after a seven-year battle this plan was defeated and the plans for highway expansions dramatically scaled back. Still, at $7 billion and together with a related new interstate spur to North Carolina, the current Virginia Department of Transportation plan would gobble up 20% of the entire state’s current transportation construction budget for the next 25 years, while serving only two of 21 localities in Virginia with population estimated to be above 90,000—and none over 100,000.

Meanwhile, Virginia’s Department of Rail and Public Transportation concluded a study showing that over 50% (and potentially many more) of through-state trucks could be diverted to a reliable, scheduled, and frequent railroad service that offered highway-competitive delivery times.

Now that the truck-only lanes controversy appears over in Virginia, zombie-like, it has arisen again along I-70 in Ohio, Indiana, Illinois, and particularly Missouri. At these links you can find groups supporting and opposing I-70 truck-only lanes.

Highways built to accommodate freight—whether typical lane expansions or truck-only schemes—are an expensive government subsidy for the trucking industry and an increasing burden on other highway users. State transportation departments lack the resources to keep up with regular maintenance schedules. The upgraded highways bring increased sprawl development—especially by-passes around cities. Sprawl consumes agricultural and forest land for “development” into residential and commercial properties and increases VMT for commuting. Highway-induced sprawl causes well-documented long-term erosion of regional energy, food, and forest production sustainability.

Unacceptable Energy Waste ~ The Hidden Internal Cost of Natural Gas Trucking

Increasing the cost of NG, affecting all customers is at the heart of Pickens plan. Those cost increases will be the obvious product of supply and demand if the bill is successful in establishing NG as a transportation fuel. However, there are significant costs resulting from this plan that don't meet the eye so readily.

NG trucks would use compressed or liquefied natural gas. According to energy researcher Alan Drake, "Compressing the gas to 2,500 to 5,000 psi takes a considerable amount of electricity. Liquefaction of natural gas takes even more energy than compression but makes liquefied natural gas (LNG) fuel much more dense than CNG (compressed natural gas), although LNG is still less than half as energy dense as diesel."[Drake, A., An American Citizen’s Guide to an Oil-Free Economy: A How-To Manual for Ending Oil Dependency With valuable bonus information on Saving Our Economy, Our Planet and Strengthening Our National Security, unpublished manuscript, 2010, copied with author’s permission.] That loss of density would require either larger on-board fuel tanks or result in reduced fuel range for trucks, negatively impacting productivity.

Drake continues:

Compressing 1.5 cubic meters of natural gas (m3) to 250 bar (US standard CNG) takes 0.7 kWh. Assuming 100% efficiency, 1.5 m3 of natural gas has the energy of 15.93 kWh. The ratio of energy just to compress CNG to the energy in CNG is 1 : 22.76 or 4.5%.

CNG engines tend to run slightly less efficiently than diesel engines. Given that double stack container trains are about 20 to 1 as efficient as diesel trucks, an electric train can carry the same cargo as CNG trucks, using just the electricity required to compress the CNG before the trucks ever move![Drake, A., email message to author]

Drake states that the inefficiencies of burning NG in individual trucks compared to burning that same NG in combined-cycle electric generating plants would result in further and substantial energy efficiency penalties. "The better solution is to burn the natural gas to make electricity that drives electric trains and not to power long haul '18 wheelers.'"[Ibid.]

Another form of NG waste is also worrisome. A substantial portion of the greenhouse gases emitted during the NG fuel usage cycle result from leakage.[Alternative and Advanced Vehicles, Alternative Fuels and Advanced Vehicles Data Center, U.S. DOE Energy Efficiency & Renewable Energy] Methane, the principal component of NG, is a greenhouse gas 23 times more potent than carbon dioxide. Increasing the probability for NG leakage across the transportation marketplace is a major climate change concern.

Transition to Natural Gas Trucking > a Staggering Public Investment ~ Cheaper and Better to Build the Steel Interstate System

We have not seen any cost projections to create the infrastructure for natural gas fueling stations. However, as cited above, Mr. Pickens states the cost for retooling America’s heavy truck fleet to burn NG is $65,000/truck engine.[Klein, P., op. cit.] This is why one bill he supports is proposing a $65,000 tax credit for converting a heavy truck engine to burn NG. Meanwhile a House bill, sponsored by Jay Inslee (D-WA) increased that proposed tax credit to $80,000/vehicle.

Infrastructure development. The bill would require the Secretary of Energy to ...[issue]

There are ample reasons why the market has not driven adoption of NG trucking:

Despite the price advantage that natural gas has had over diesel fuel in recent years (an advantage that is projected to increase over time…), other factors—including higher vehicle costs, lower operating range, and limited fueling infrastructure—have severely limited market acceptance and penetration of natural gas vehicles. As of 2008, trucks powered by natural gas made up only 0.3 percent of the heavy truck fleet, or about 27,000 of the 8.7 million registered heavy trucks…high incremental costs keep the fleet of [heavy duty natural gas vehicles] HDNGVs relatively small, at 1.7 percent (260,000 vehicles) of the total stock of 15 million heavy trucks on the road in 2035.[U.S. Energy Information Agency, Annual Energy Outlook 2010 with Projections to 2035, Report #: DOE/EIA-0383, May 11, 2010]

No technological improvements and cost reductions in natural gas storage appear on the horizon:

By far the largest [NG conversion] cost is the fuel storage system… Because tank technology is fairly mature and, in the case of cylindrical tanks to hold gases at high pressure, is already widely deployed, the [analysis] does not assume significant reductions in incremental vehicle costs over time. [Ibid]

As noted above, using the $65,000 as a standard, retooling the entire fleet of U.S. heavy trucks would cost the taxpayers over half a trillion dollars, without considering any costs related to building a NG refueling network. The entire, electrified U.S. Steel Interstate System would cost between $415-680 billion.[Drake, A., Op. cit.] The Class 1 railroads are committed to $142 billion in system infrastructure improvements,[Ibid] much of which would be part of the Steel Interstate System. Retooling truck engines would be the tip of the cost iceberg—highway infrastructure improvements and road maintenance costs accommodating the nearly double current truck numbers and their vehicle miles traveled (VMT) projected by 2035 would be far higher. In fact, a case could be made for the Steel Interstate option as paying for itself in avoided future highway maintenance costs with significantly reduced truck VMT[Ibid] and reduced political pressure to allow heavier and heavier trucks on the highways.

Photo: HUPAC

Investments in the nation’s rail system will significantly improve rail freight and passenger capacity; whereas, similar amounts of money invested in truck conversion to NG yield zero transportation capacity improvements. To avoid national gridlock, highways would still have to be expanded with additional public monies to accommodate additional trucks, regardless of their use of NG or diesel fuels. Further, investments improving rail infrastructure offer a much higher rate of return on transportation capacity or productivity than similar investments in highway expansion.

Investments in the nation’s rail system will significantly improve rail freight and passenger capacity; whereas, similar amounts of money invested in truck conversion to NG yield zero transportation capacity improvements. To avoid national gridlock, highways would still have to be expanded with additional public monies to accommodate additional trucks, regardless of their use of NG or diesel fuels. Further, investments improving rail infrastructure offer a much higher rate of return on transportation capacity or productivity than similar investments in highway expansion.

The more society uses roads, the more expensive and slower it becomes. Highway and road expansion projects show that the marginal cost for extra capacity is higher, usually far higher, than the original inflation adjusted cost.

The opposite is true for rail. Extra capacity on existing Right-of-Way (ROW) is usually significantly cheaper than the base costs. The more “we” use rail, with appropriate infrastructure investments, the cheaper and faster transportation by rail becomes.

Roads have unrestricted access and need to be sized to meet peak demand. Roads also create their own demand over time, so we simply cannot build “enough” roads, or buy enough oil to operate on them. More roads is not the answer.[Ibid.]

The Steel Interstate could be constructed in just six years, with the most important capacity improvements made first for the earliest return on investment. Capacity increases to interstate and other major highways would take longer to implement and be more costly than the original highway costs.[Ibid]

Investments in rail instead of NG retrofits and highway infrastructure would not only increase safety and greatly reduce highway maintenance costs, but go much further towards reducing the nation’s contribution to climate change. Less highway construction and resulting loss of forests and pastures to pavement and energy-intensive sprawl development will also limit greenhouse gas emissions.

That "Chicken and Egg" Thing ~ Natural Gas Conversion Faces Market Penetration Barriers

The pace of NG truck conversion is complicated by the chicken and egg problem. On one hand, sufficient and sufficiently widespread NG fueling stations must be in place before truck fleets and owner-operators risk converting their rigs to burn natural gas. On the other, it is difficult to sign on these new filling stations until sufficient trucks, burning NG, travel in the highway corridor where service station owners are considering the conversion. Further, truck engine manufacturers will not produce NG burning models without a fueling infrastructure and demonstrable demand for these trucks in place.

These are barriers that already limit the introduction and use of electric-powered vehicles, but unlike those vehicles, truck owners will not be able to plug their rigs into the electric circuits at home for commuting purposes. Operating a fleet of NG trucks or buses from a central dispatch and fueling point for local routes is a practical application for NG conversion, but the trucking conversion Pickens-Reid proposes to finance is over-the-road. Range restrictions or fuel uncertainty for over-the-road trucking is fatal for conversion.

These are barriers that already limit the introduction and use of electric-powered vehicles, but unlike those vehicles, truck owners will not be able to plug their rigs into the electric circuits at home for commuting purposes. Operating a fleet of NG trucks or buses from a central dispatch and fueling point for local routes is a practical application for NG conversion, but the trucking conversion Pickens-Reid proposes to finance is over-the-road. Range restrictions or fuel uncertainty for over-the-road trucking is fatal for conversion.

Even if the refueling station problem is solved, market penetration for NG truck conversion is still restricted by limitations that fuel storage systems place on vehicle range before required refueling. Reduction in vehicle range costs time which precipitates losses in transportation productivity:

A diesel truck with one 150-gallon diesel tank and a fuel economy of 6 to 7 mpg can drive approximately 1,000 miles without refueling, which can be extended readily with an auxiliary fuel tank. In contrast, a CNG-fueled truck with a frame-rail-mounted storage tank can drive only about 150 miles without refueling, while one with a back-of-cab frame-mounted storage tank can drive about 400 miles without refueling, similar to a LNG-fueled truck with frame-rail-mounted tanks. In addition, regardless of fuel type, long-distance trucks are less likely to be fueled at central bases, which make them more dependent on fueling infrastructure that is open to the public.

In addition to concerns about driving range and refueling, the residual value of [NG trucks] in the [resale] market is likely to be an important consideration for buyers. Also, purchase decisions can be influenced by other factors, such as weight limits on highways and bridges, which can make the considerable additional weight of CNG or LNG tanks a significant drawback in some market segments.[Ibid]

On the fueling station side, there are similar cost barriers to market implementation:

[Heavy duty NG vehicles] cannot gain a major share of the heavy truck market in the absence of major investments in natural gas fueling infrastructure. The assumed $100,000 tax credit per filling station is a relatively small percentage of the estimated $1 million to $4 million cost for such facilities. Assuming an initial cost of $2 million per station, Filling station conversion table shows the levelized capital cost of the station per gallon of diesel equivalent refueling capacity with and without the $100,000 tax credit, for station fuel throughput capacities of 1,250, 5,000, and 12,500 gallons per day.

As indicated in [the U.S. Department of Transportation] filling station conversion table, increasing the throughput capacity of a fueling station from 1,250 to 5,000 gallons diesel equivalent per day lowers the capital cost recovery component of supplying natural gas fuel to [converted trucks] by more than $1.00 per gallon of diesel equivalent. The infrastructure tax credit lowers the capital cost recovery component by only an additional 8 cents per gallon for the smallest facility size shown in the table and by only 1 cent per gallon for the largest facility size. This suggests that throughput capacity (demand) is a far more important consideration for decisions about investment in natural gas fueling stations than are potential tax credits on the order of about $100,000.[Ibid] Image: Craig Thorpe

The costs of such a large-scale, untried conversion would be better allocated towards a proven technology—intermodal rail. Government support for upgrading the railroad infrastructure would yield a far larger freight capacity increase and offer the additional benefit of much faster and more useful passenger rail system.

Environmentally Safe? "Fracking" Threatens Groundwater and Human Health

T. Boone Pickens and some others have touted the idea of conversion to NG as a transportation fuel because of the abundance of this fossil fuel being brought onto the market with the advent of a new NG drilling technology called hydraulic fracturing or “fracking” for short. In fact, it is fracking of shale strata that has markedly increased the reserves of NG in the U.S., making the prospect of employing it for a transportation fuel even possible.

"Hydraulic fracturing is a process used in nine out of 10 natural gas wells in the United States."[ProPublica, "What is Hydraulic Fracturing?"] The Environmental Protection Agency is studying the impact of hydraulic fracturing under a 2009 Congressional mandate. If fracking becomes legally constrained, then natural gas will be in short supply and very expensive and converting our truck fleet to natural gas will be a very bad investment.

Fracking was introduced by the Halliburton Corporation after the company procured a specific exemption from the Clean Drinking Water Act in 2005. The exemption allows use of proprietary chemicals, injected into the rock along with thousands of gallons of water for every well. The gas industry opposes efforts aimed at public disclosure. Because the chemicals are protected as proprietary by the congressional exemption, no water quality specialists are aware of what these chemicals are and what potential contamination hazards they hold for household wells and public drinking water drawn from ground water sources. The problem is similar for farms and ranches dependent on ground water for livestock or irrigation. Halliburton failed to comply with a voluntary request from the EPA to turn over its list of fracking chemicals. All other companies are complying; EPA had to subpoena Halliburton for this proprietary information.[Rudolf, J., E.P.A. Subpoenas Halliburton on Fracking, New York Times, 11-9-10.]

In sparsely populated Sublette County in Wyoming, which has some of the highest concentrations of wells, vapors reacting to sunlight have contributed to levels of ozone higher than those recorded in Houston and Los Angeles. The demand on water used in the fracking process can have a seriously negative impact on regions where potable groundwater is in short supply. Pollution of groundwater of course is a universal concern. Citizens, who live in areas where fracking is occurring, report well water that catches on fire and skin rashes and burns from showering with well water.

Image: "Gasland," directed by Josh Fox

Image: "Gasland," directed by Josh Fox

Environmental Protection Agency internal reports show that "EPA scientists are alarmed, warning that the drilling waste is a threat to drinking water in Pennsylvania," and that fracking "wastewater, which is sometimes hauled to sewage plants not designed to treat it and then discharged into rivers that supply drinking water, contains radioactivity at levels higher than previously known, and far higher than the level that federal regulators say is safe for these treatment plants to handle...Most drinking-water intake plants downstream from those sewage treatment plants in Pennsylvania, with the blessing of regulators, have not tested for radioactivity since before 2006, even though the drilling boom began in 2008.".[Urbina, I., "Regulation Lax as Gas Wells’ Tainted Water Hits River," New York Times, 2-26-11]

"Air pollution caused by natural-gas drilling is a growing threat, too. Wyoming, for example, failed in 2009 to meet federal standards for air quality for the first time in its history partly because of the fumes containing benzene and toluene from roughly 27,000 wells, the vast majority drilled in the past five years."[Ibid]

New York Times investigative series on hydro-fracking: Journalist Ian Urbina wrote a series of investigative stories about NG fracking that appeared in the Times between February 27 and March 4, 2011. The series, "Drilling Down," especially focuses on hydrofracking chemical waste, revealing a NG industry vehemently opposing and frequently exempt from regulation at virtually every turn and state and federal environmental and safety protection officials technically unable to meet the regulatory challenge and politically hamstrung--with environmental and public health advocates clearly outmaneuvered:

- Many EPA scientists have expressed alarm through official channels at the industry practice of dumping radioactive materials such as radium, into Pennsylvania municipal treatment plants unequipped to make such waste safe for drinking for customers of municipal water systems downstream.

- Industry points to growing recycling of hydrofracking wastes, but the Urbina determines that recycling has yet to exceed 50% of the fracking wastewater generated by well fracking in Pennsylvania in the past 18 months ending December, 2010). Even where waste is recycled the industry program is failing to solve all the health and safety wastewater problems.

- In "Pressure Limits Efforts to Police Drilling for Gas," Urbina documents political pressure inhibiting appropriate EPA regulation of NG industry practices.

- Also available are documents used in the "Drilling Down" investigation, maps of wastewater contamination sites in PA, graphic explanations of how fracking works to increase NG produced and what toxic chemicals are utilized in fracking operations, and a video of individuals claiming health damage from breathing air contaminated by volatile chemicals emitted from NG wells.

Handling the wastewater and chemicals from fracking is a wide-ranging problem. On March 3, 2011, Huffington Post reported that two NG drilling companies have temporarily suspended pumping fracking waste into high-pressure injection wells, where the Arkansas Oil & Gas Commission suspects the waste injection of causing earthquakes, unusual for the area. Since drillers have stopped using the well, Earthquakes have declined noticeably.

The developing literature concerning the environmental consequences of NG fracking on groundwater and related environmental and health impacts is too extensive to attempt to summarize here completely. Suffice it to say that the legal protections for the drilling practice are under attack from those who live near where fracking is practiced.[Clayton, M., “Fracking for natural gas: EPA hearings bring protests” Christian Science Monitor, 9-13-10.] Citizens have organized to fight the practice. New citizens' web sites are appearing--such as this one on November 1, 2010. There is a bill before the New York legislature to place a moratorium on fracking until the state can gear up regulatory infrastructure to monitor the practice. New rules issued by the Wyoming Oil and Gas Conservation Commission are attempting to disclose chemicals used in fracking there. There are air quality as well as water pollution concerns. An Academy Award-nominated documentary film, "Gasland," documents growing popular opposition to fracking.

Sustainable Transportation Fuel? Reliability and Appropriateness of Natural Gas as a Transportation Fuel is Suspect

The academic literature on fracking is developing. Because reduction in greenhouse gases is being touted as one of the reasons for switching from diesel-powered transportation to natural gas, it is clear we must heed Robert Howarth, Renee Santoro, and Tony Ingraffea's conclusion about the life-cycle greenhouse gas emissions from NG obtained by hydraulic fracturing. This new research deserves focused attention of all appropriate national policy makers:

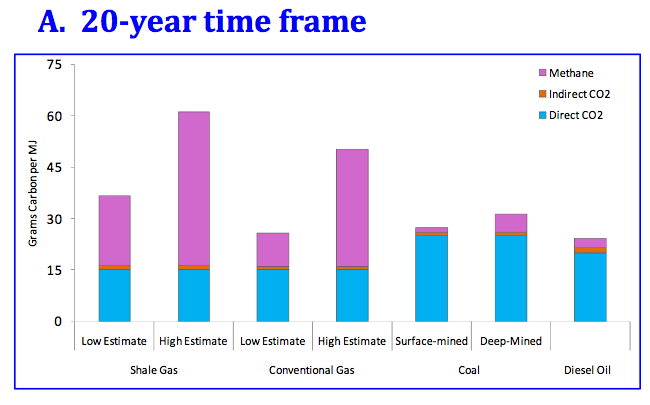

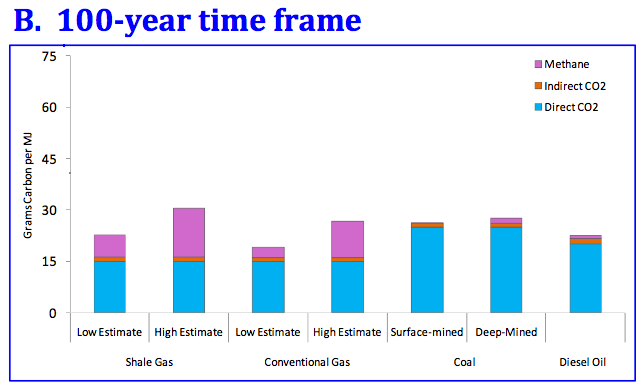

Natural gas is composed largely of methane, and 3.6% to 7.9% of the methane from shale-gas production escapes to the atmosphere in venting and leaks. This is 1.3- to 2.1-times greater methane emissions than from conventional gas. The higher emissions from shale gas occur at the time wells are hydraulically fractured -- as methane escapes from flow-back return fluids -- and during drill out following the fracturing. Methane is a powerful greenhouse gas, with a global warming potential that is far greater than that of carbon dioxide, particularly over time periods of a couple of decades following emission. Methane contributes substantially to the greenhouse gas footprint of shale gas on shorter time scales, dominating it on a 20-year time frame. The footprint for shale gas is greater than that for conventional gas or oil when viewed on any time frame, but particularly so over 20 years. Compared to coal, the footprint of shale gas is 1.2- to 2.1-fold greater on the 20-year time frame and is comparable when compared over 100-years.

Graphs: Howarth, R., Santoro, R., and Ingraffea, T., Methane and the greenhouse gas footprint of natural gas from shale formations, Climatic Change Letters, in press, 2011.

We urge caution in viewing natural gas as good fuel choice for the future. Note that both the National Academy of Sciences and the Council of Scientific Society Presidents have urged great caution before proceeding with the development of diffuse natural gas from shale formations using unconventional technology.[Howarth,R., Santoro, R., and Ingraffea, T., Methane and the greenhouse gas footprint of natural gas from shale formations, Climatic Change Letters, in press, 2011, emphasis added]

There are so many environmental, health, and safety concerns being expressed from citizens and regulators that the long-term viability of fracking for NG is not secure. Loss of fracking or partial loss would greatly reduce currently available NG reserves in North America. Now, Mr. Howarth's analysis strongly calls into question whether NG from fracking is any more sustainable with reference to climate change than our current diesel-powered truck freight system.

Using NG as a transport fuel when we have a clearly better option in the Steel Interstate, would be burning NG without regard to conserving it for it's higher uses, both now and in the future. "We need to save NG for heating, fertilizer, industrial uses and electrical generation," says energy researcher Alan Drake.[Drake, A., email message to author]

The Steel Interstate System offers the promise of facilitating transmission and therefore production of renewable wind and solar energy. When powered by renewable energy, the SIS would be virtually greenhouse gas emission-free. The SIS would promote renewable electricity generated in remote locations—the Great Plains, desert Southwest, and Coastal Plain—by offering single-owner rail right-of-ways for power transmission to urban markets.

The Steel Interstate System offers the promise of facilitating transmission and therefore production of renewable wind and solar energy. When powered by renewable energy, the SIS would be virtually greenhouse gas emission-free. The SIS would promote renewable electricity generated in remote locations—the Great Plains, desert Southwest, and Coastal Plain—by offering single-owner rail right-of-ways for power transmission to urban markets.

The Millennium Institute determined that using the same fiscal resources required to convert, fuel, and sustain highway infrastructure for NG trucking, a Steel Interstate System could be financed and go a long way towards support for constructing urban transit across the U.S. These two transportation investments would make a large reduction in the nation’s contribution to greenhouse gases and would save both petroleum and natural gas for future higher uses than as a transportation fuel. These two transportation investments significantly increase transportation productivity and improve Gross Domestic Product (GDP) rather than place a drag on the macro-economy.

With an estimated total investment of $250-500 billion ($12.5-$25 billion/year in inter-city railroad lines inter-city railroad lines No-Oil Transportation could supplant most inter-city truck freight and unspecified modal share of passenger service. Up to $60 billion/year ($1.2 trillion over 20 years), spent cost effectively on urban rail, should allow for 28% annual growth (not compounded) in urban passenger miles on Non-Oil Transportation.

These two investment create a 11% larger GDP, only 4% increase in Greenhouse Gas Emissions and a 26% reduction in oil consumption already in 2030 versus a strictly market-based reaction. Adding renewable energy improved the results to GDP +13%, GHG -38% and oil consumption -22%.[Drake, A., Bassi, A.M., Tennyson, E.L., and Herron, H.R., Evaluating the Creation of a Parallel Non-Oil Transportation System in an Oil Constrained Future -- Millennium Institute, January, 2010. Abstract pgs. 1-2.]

Although there are many reports that shale and coal-bed methane sources are greatly adding to the proven reserves of NG in the U.S., not everyone is in agreement that our natural gas supply will stretch far out into the future. Art Berman is a geological consultant whose specialties are subsurface petroleum geology, seismic interpretation, and database design and management. He is currently consulting with a wide range of industry clients such as PetroChina, Total, and Schlumberger.

If you investigate the origin of this supposed 100-year supply of natural gas…where does this come from? If you go back to the Potential Gas Committee’s [PGC] report, which is where I believe it comes from, the technically recoverable resource they describe, and you divide it by annual US consumption, you come up with 90 years, not 100…What they’re saying is that if you pin this thing down where there have actually been some wells drilled that have actually produced some gas, the technically recoverable resource is closer to …about 7 year’s worth of US supply from shale. I happen to think that that’s a pretty darn realistic estimate...

The resource hasn’t been misrepresented but the probable component has not been properly explained as a much smaller component of the total resource; I guess they just didn’t read the PGC’s report carefully enough. If you take the proved reserves plus the report’s probable technically recoverable number, we have something like 25 years of natural gas supply in North America.[Berman, A., interview, Peak Oil Reference, Association for the Study of Peak Oil and Gas, July 19, 2010]

Coal-bed methane presents even greater risk of contamination of domestic groundwater resources. Still “recent U.S. estimates (Rice, 1997) indicate more than 700 trillion cubic feet (TCF) of coalbed methane gas in place, with over 100 TCF economically recoverable--a five-year supply at present rates of consumption.”[U.S. Geological Survey, Coalbed Methane and Coal Stratigraphy Research]

Whether or not these estimates are low for the shale and coal-bed methane, it is clear that natural gas is not a limitless resource. There is certainly reason for concern that the ebullient projections for recoverable NG in the U.S. may be too optimistic. In any case, do we want to spend billions converting a significant portion of our transportation sector to a depletable NG resource that will certainly result in acceleration of that depletion rate?

If NG is to be employed as a transportation fuel, it would be far more efficient to use the NG to power electric power plants. Combined-cycle NG power plants are 50-60% efficient. Using NG to power an electric train will use about 1/10th to 1/15th the NG that a NG trucks require to move the same cargo.[Drake, A., email message to author]

The Steel Interstate Simply is Safer ~ Move Freight on Trains, Off the Roads

The Steel Interstate Simply is Safer ~ Move Freight on Trains, Off the Roads

Converting more trucks to NG, thus adding to the already bloated national fleet of trucks on our highways, will erode, not improve, highway safety. Alternatively, investing the same money into a Steel Interstate rail system offers greater safety for all motor vehicle drivers and especially for passengers choosing the expanded and improved passenger rail system instead of driving.

Natural gas presents significantly greater problems related to flammability. Natural gas receives the highest hazard ranking for flammability, according to the National Fire Protection Association. The Association categorizes diesel as moderately flammable. Compressed or liquified NG also presents greater storage hazards than diesel fuel.[Swartz, N., Trucks: Fueling the Diesel vs. Natural Gas Debate, Waste Age, 5-1-2000]

Productivity ~ The Right Choice Enhances National Competitiveness

Transportation productivity will continue to deteriorate and cost of goods hauled will escalate if more trucks are added to the overburdened interstate highway system. This will increase costs and reduce international competitiveness across the economy. The Steel Interstate, on the other hand, will reduce transportation costs, increasing productivity for every item shipped.

The demand for drivers will increase despite the shortage of those willing to risk erosion of their family life to adopt an over-the-road trucking work life. No suggestion has been offered to address this chronic labor shortage. Resorting to the introduction of Mexican trucks and drivers would raise serious safety and labor problems. This is a shortage we don't need to exacerbate.